Our company architect and structural engineerwas created with the aim of promoting architectural design and support the work of colleagues involved in implementation with state-of-the-art assessment technologies. Our area of expertise is building surveywhere we use high-precision laser scanners to record the current geometry of buildings and structures. Several years professional experiencesand our modern equipmentguarantees the high qualityhighly accurate measurement results.

Our goal is to establish long-term cooperatio with engineers, contractors and design offices for whom competitive knowledge is essential, and who are ready to integrate the latest professional innovationsinto their projects.

Our services support architectural, mechanical and interior design, heritage conservation, as well as long-term monitoring and BIM projects.

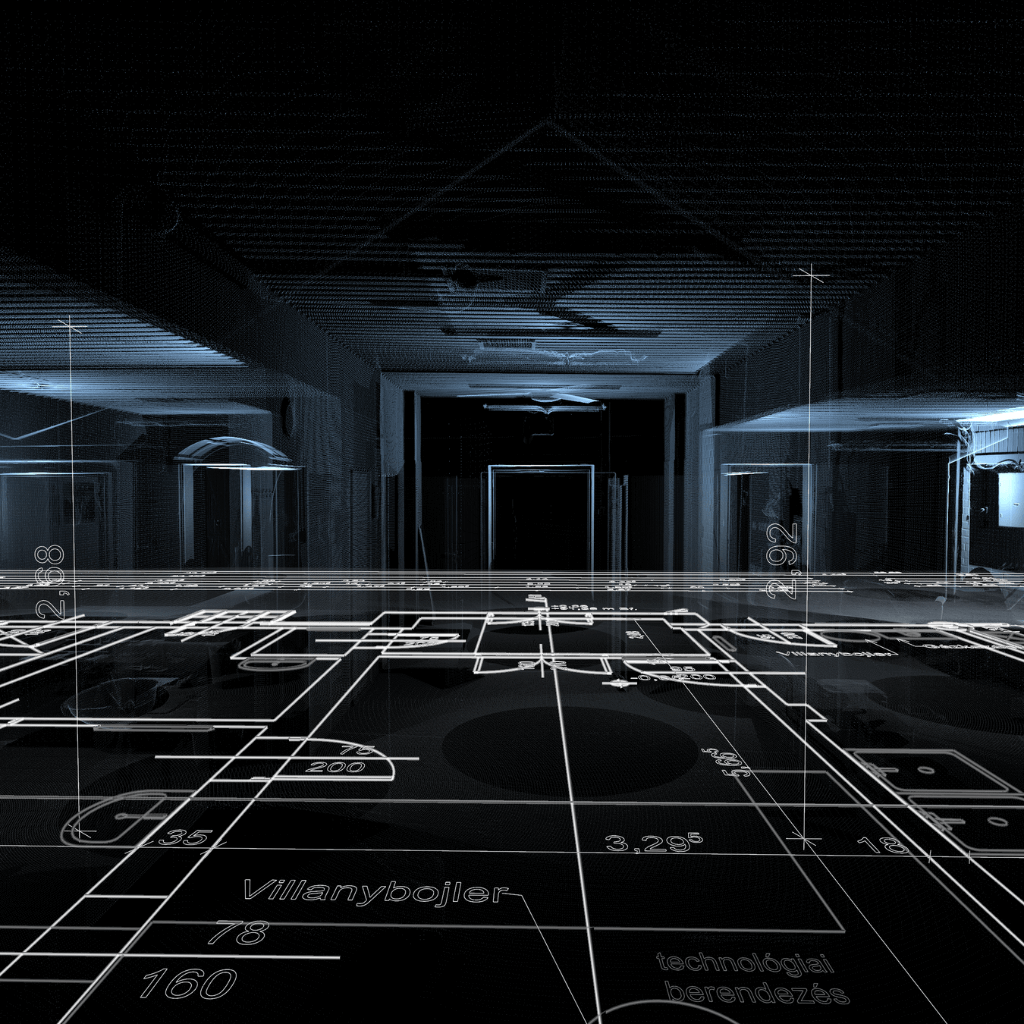

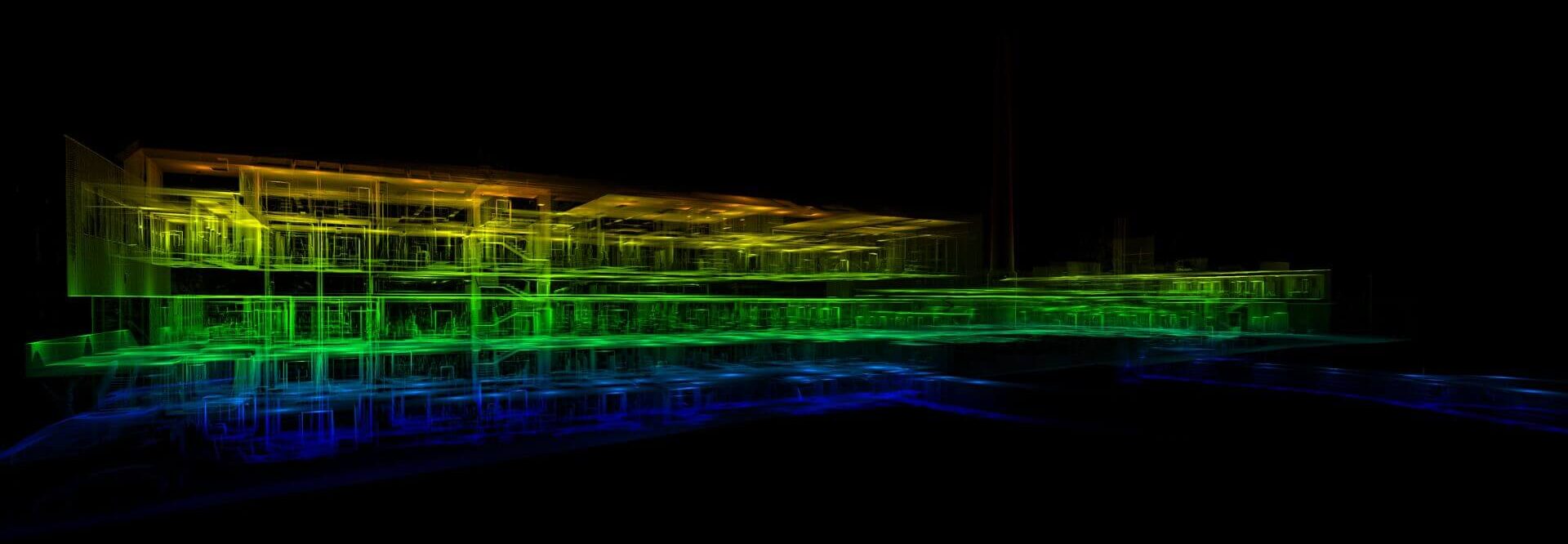

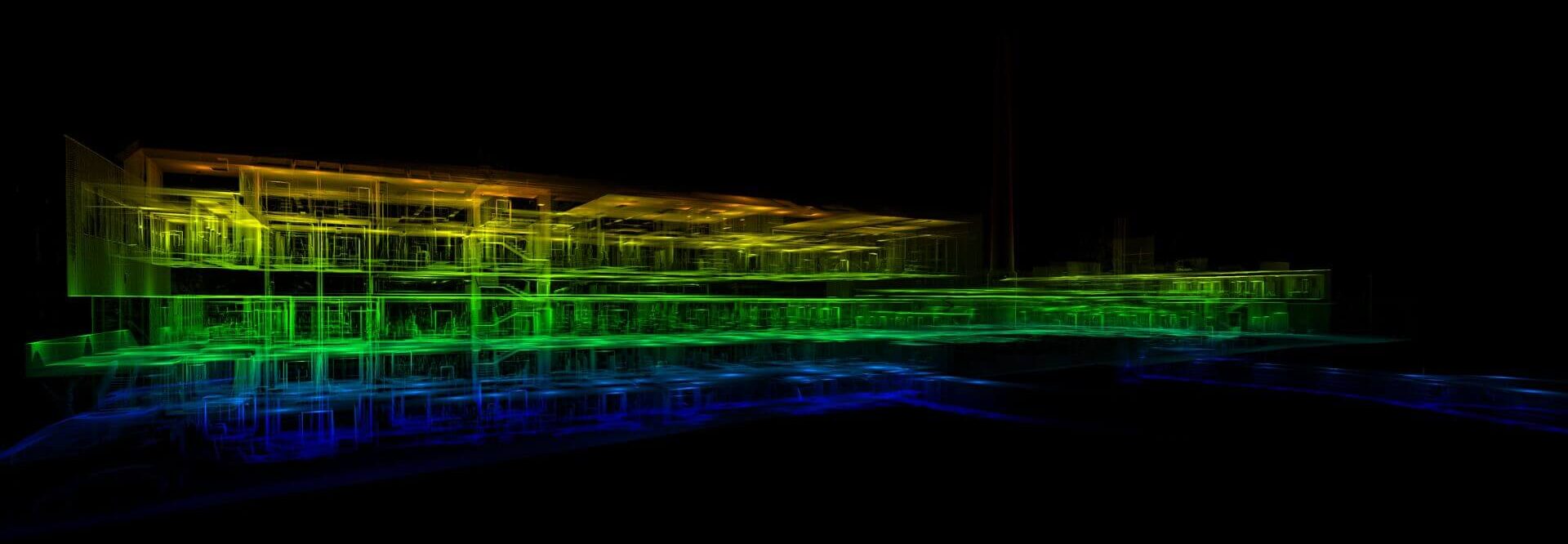

A 3D laser scanner is a measuring device that quickly capture the geometry and colour of buildings and parts of buildings with high accuracy. The laser scanner emits laser beams that are reflected from the surface of the building, and measures their reflection time to create a three-dimensional point cloud. This point cloud provides a detailed digital copy of the building, which is for design, renovation or documentation purposes. The data thus obtained allow the architectural accurate and efficient preparation of design documentation, the preparation of the a detailed assessment of the condition of existing buildings.

Photogrammetry is a measurement technique that uses photographs to create accurate three-dimensional data and models. By applying create detailed 3D models. In contrast to 3D scanning, which uses structured laser light to measure the location of points, the photogrammetry using actual images to capture an object and turn it into a 3D model.

The advantages of photogrammetry include:

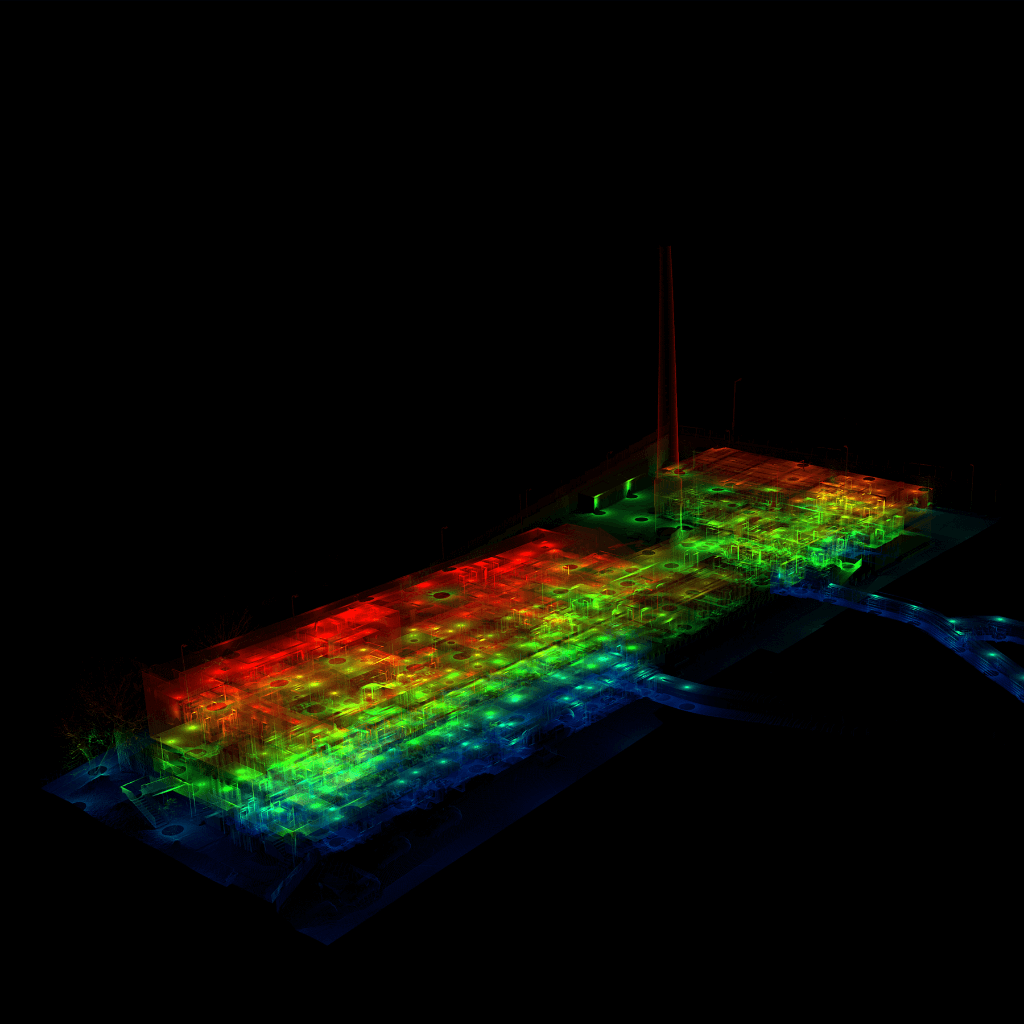

We use a combination of the technologies described above to achieve the best results. There are details of the structures that would not be visible from a position where the scanner could be installed. We try to minimise the resulting information gap by using drones. The process is carried out using a „FARO s70” instrument by ground laser scanning begins, which ensure the necessary accuracy (+-1-2mm). Depending on the size of the object and the complexity of the ground plan, measurements are taken from several positions, and then, in places where a view could not be provided, a „DJI PHANTOM 4” take pictures with a drone. These are then photogrammetrically combined to produce a cloud using software. After combining the results from the different positions extracted from the scanner, a drone measurement is fitted to the existing measurement. Since the scanner cloud is used as a reference, the accuracy of the measurement is preserved, but a point cloud of the entire structure is available.

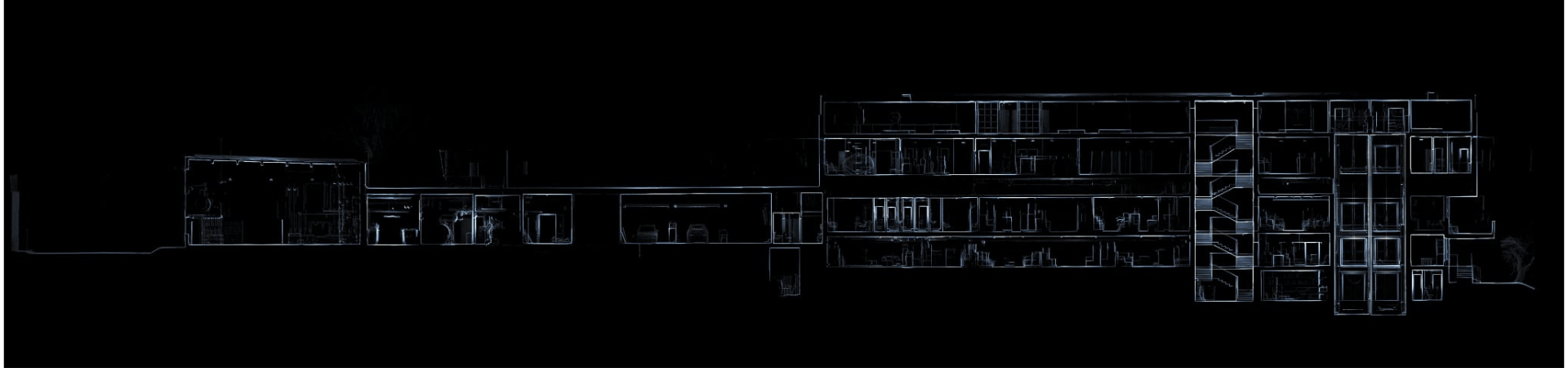

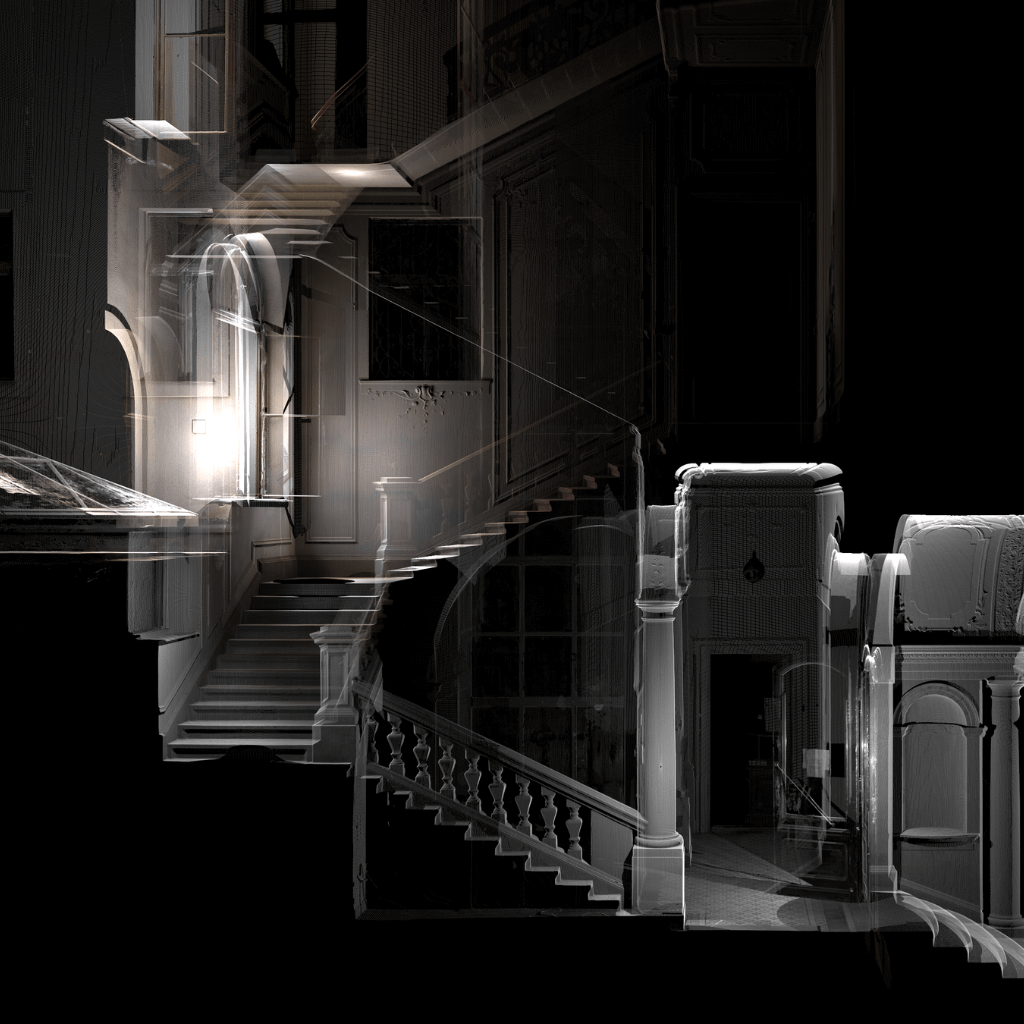

During the project, we were commissioned to carry out a full survey of a disused hotel building, including the external facade and the internal attic. For the façade survey, we used a ground laser scanner, while the hard-to-reach, non-visible parts were surveyed by drone. The survey was made difficult by the fact that the building is not walkable and the façade was covered with creeping plants, which both damaged the plaster layer and made the measurements difficult. The wind was constantly moving the vegetation, which would have been a disturbing factor when recording the point cloud. To avoid this, we worked with a high number of measurements. Two different measurement technologies (laser scanner, drone photogrammetry) were used to produce the point cloud. The matching of the point clouds produced in this way required more post-processing. After registering and verifying the point cloud, we obtained a coloured point cloud containing the exterior and interior spaces of the building. Using the point cloud, we were able to pinpoint damaged areas of the façade and roof structure, as well as defects in the tile roofing. The map helped us to achieve significant cost savings for the investor, as we were able to pinpoint the exact parts of the building to be repaired and their exact positions. In addition, the 3D model made it easy to calculate the quantities of materials, which saved the contractor even more time.

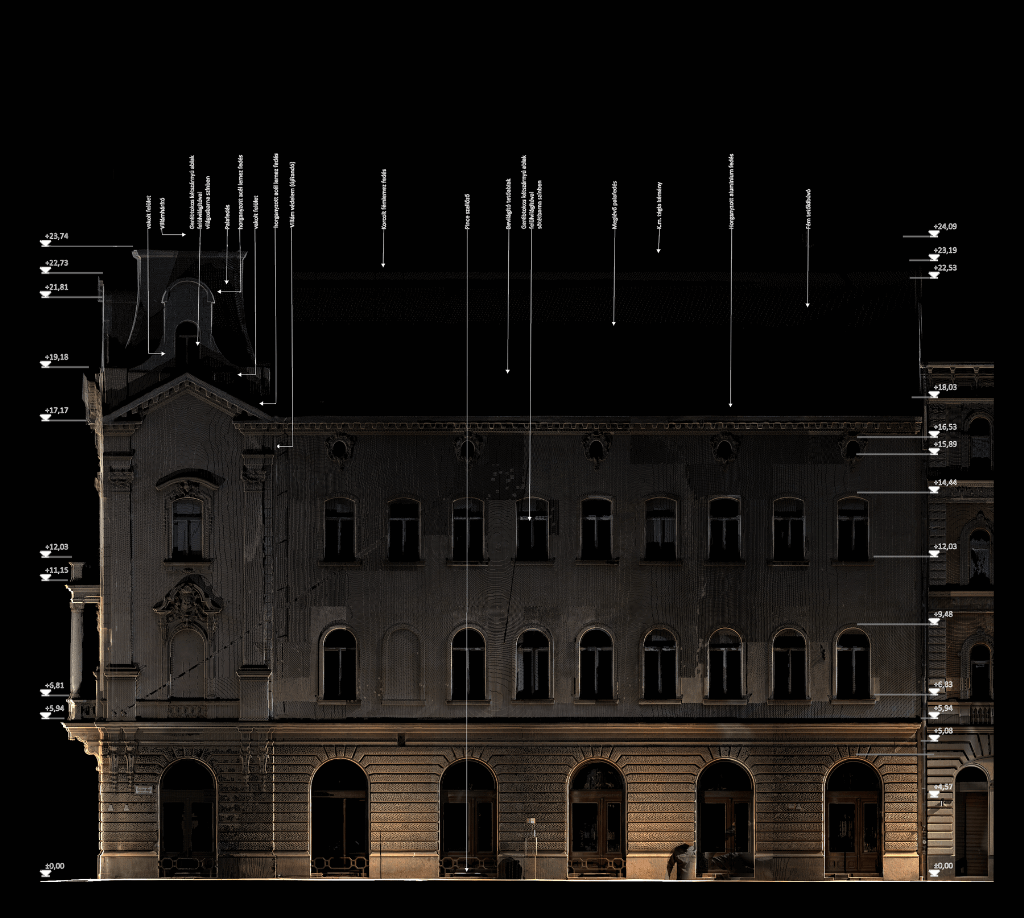

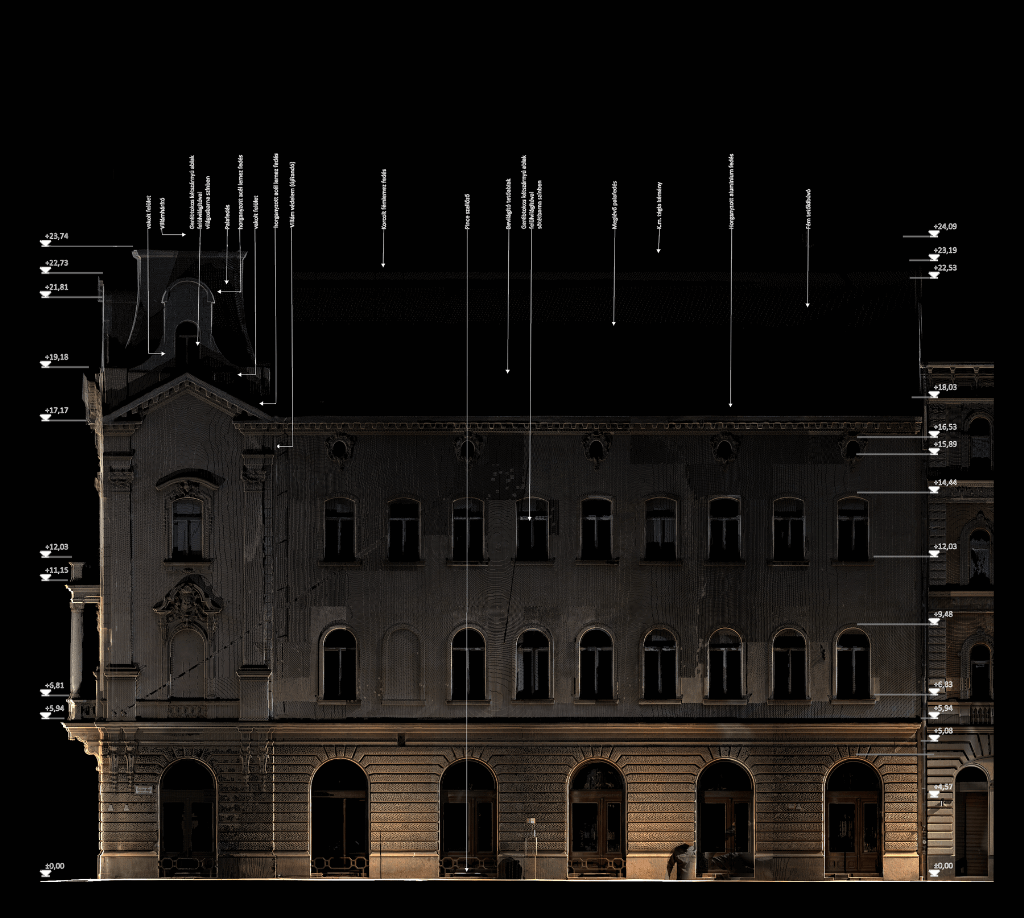

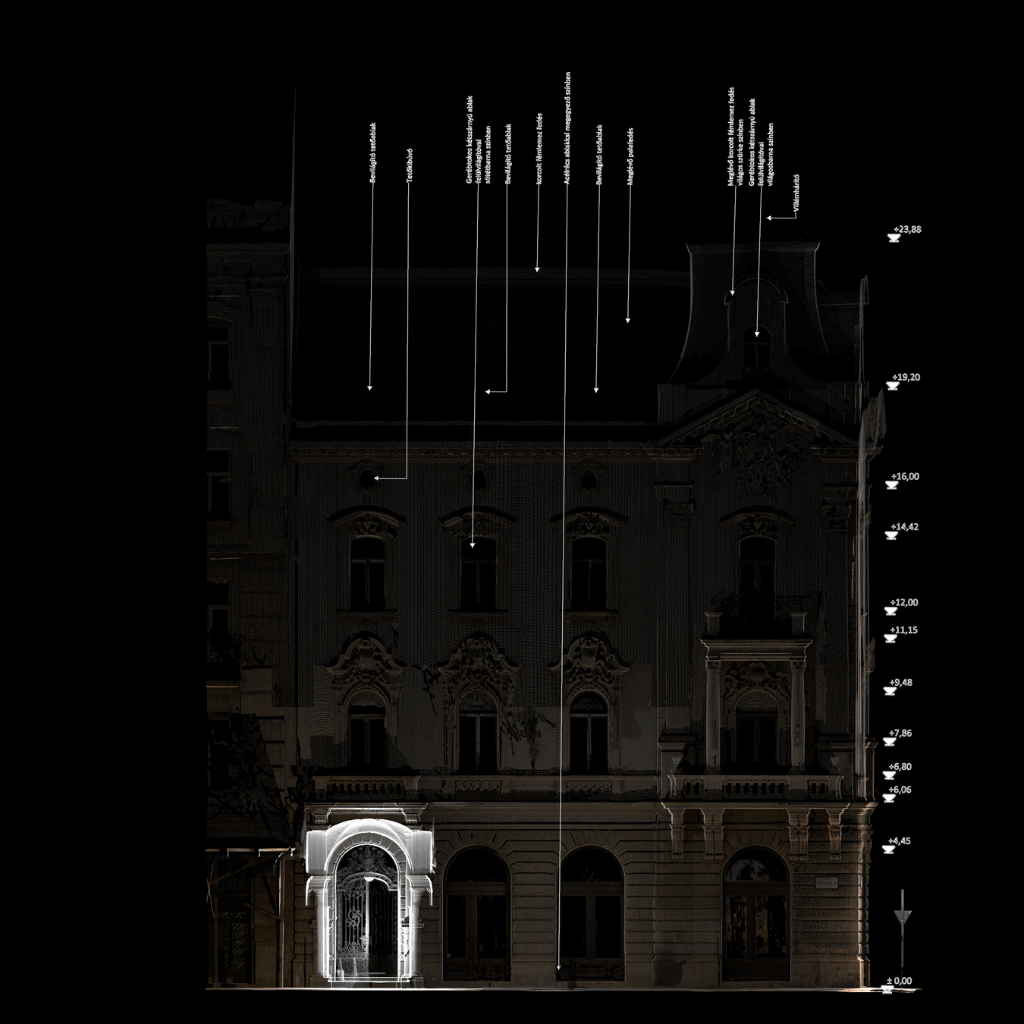

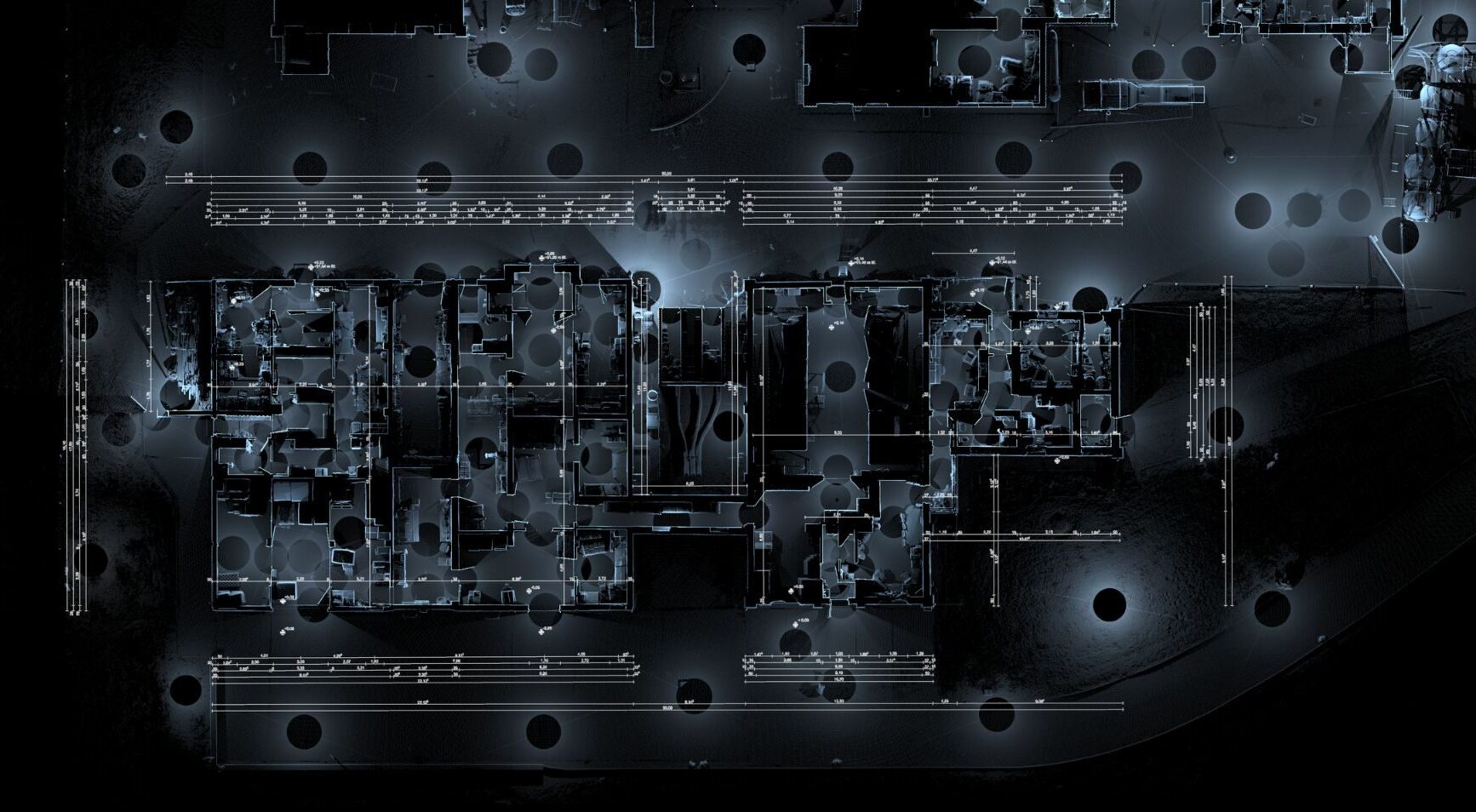

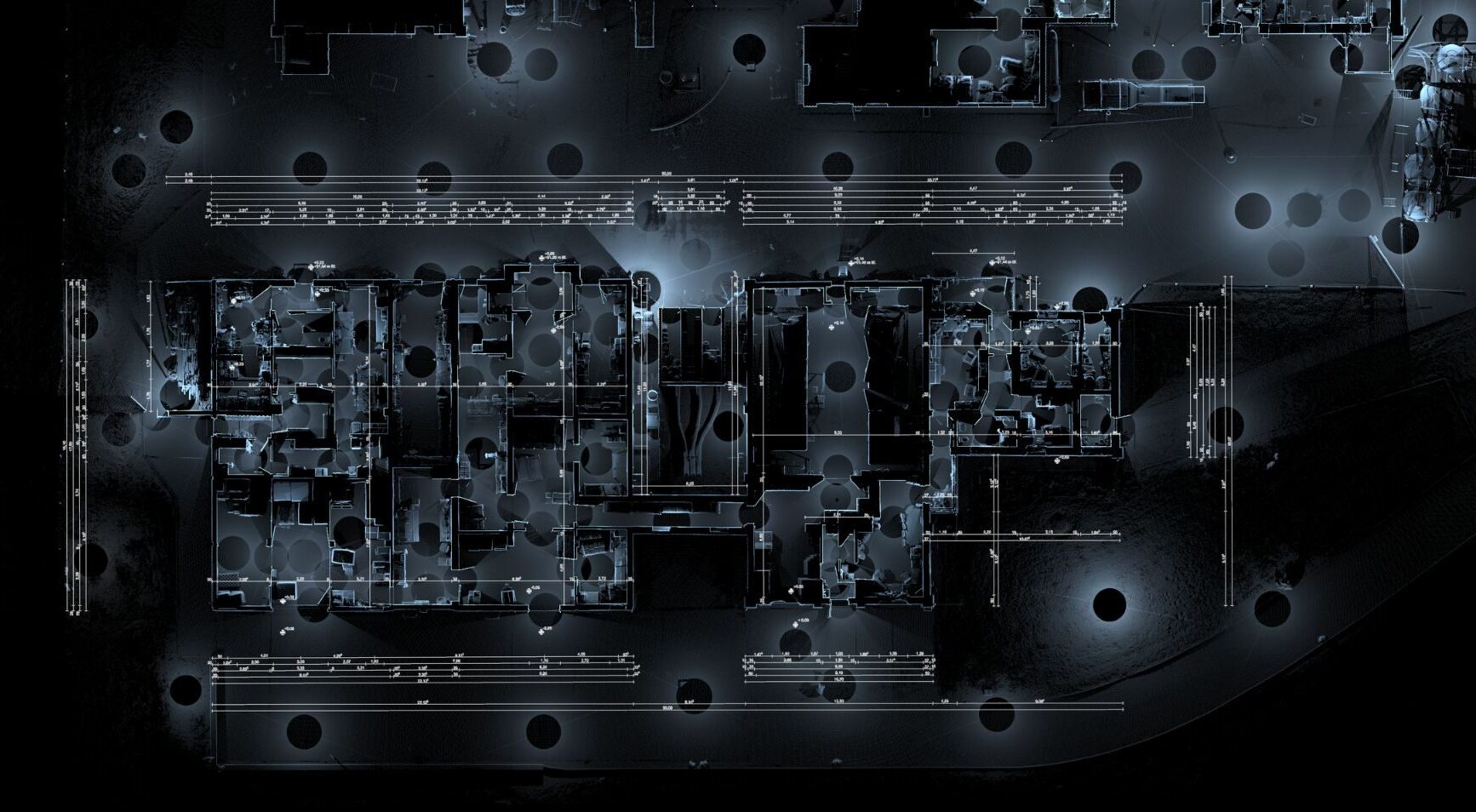

During the work, we were commissioned to survey the exterior and interior facade of the listed building located at 25 Alkotmány Street, Budapest. The building was easily accessible from all sides, so the street and the inner courtyard facades were surveyed with a ground laser scanner. In order to ensure that the point cloud contained as much detail as possible of the façade's decorative elements, we used a higher resolution measurement time of 7-10 minutes. The measurement of the roof pitches was angle of view, we were not able to measure the roof dome with a ground scanner, so we used a drone to measure the hard-to-see areas. In post-processing, the ground and aerial measurements were merged and used to create a high-detail point cloud.

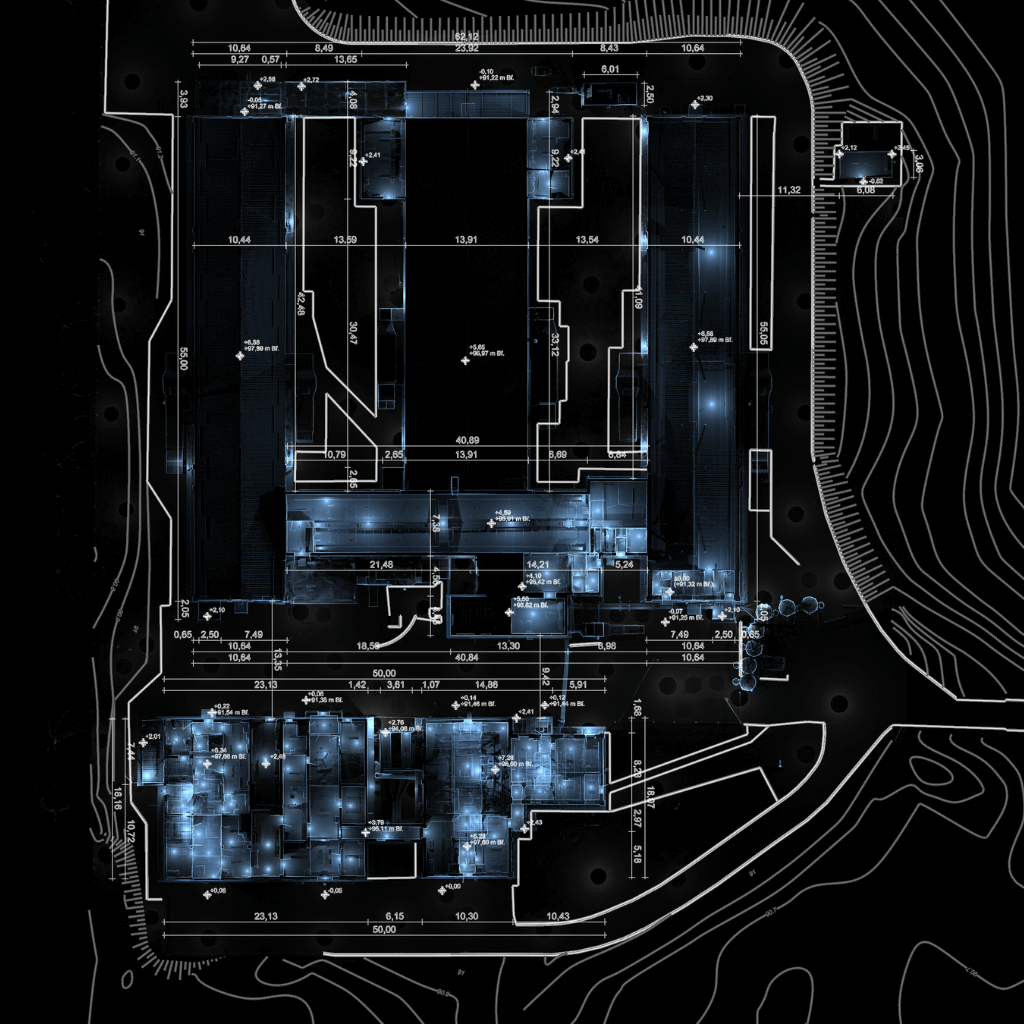

Unused brickworks - a drone survey was carried out for the concept plan. The task was to survey a disused brickworks of more than 11 000 m² and its immediate surroundings. The client's objective was to prepare an architectural concept plan, which required in particular an accurate recording of the terrain and the location of the buildings. Due to the steep slope of the terrain and the large extent of the site, a drone survey was chosen to allow rapid data collection. Although the technology has an accuracy of 5-10 cm and is therefore slightly less precise than laser scanning, it provided sufficient accuracy to produce a concept plan. The advantage of the decision was that the drone survey could be carried out in a significantly shorter time, which the client deliberately chose to ensure a quick result. In total, the field walk and flight took approximately 2 hours and the point cloud processing took a further 1 working day. The result was a detailed point cloud covering the entire area, including the terrain, building positions, roofs and the distribution of windows. The resulting model provided a reliable basis for building the architectural 3D model and preparing the concept plan.

The project involved an internal and external survey of the halls and social building of an egg factory. The 8000 m² 8000 m2 area, there are three social buildings and five halls with a total built-up area of 3100 m². Due to the complexity of the internal areas of the social building, we were able to obtain high measurement figures. of the building. The survey could only be carried out during the periodic clean-ups due to the continuous operation of the premises, so the work was carried out in five phases. After each measurement phase, the updated point clouds were sent to our architectural client so that he could carry out his design work in parallel. In total, over 300 measurements were used to produce a detailed point cloud, which provided the architect with a basis for the survey plans.

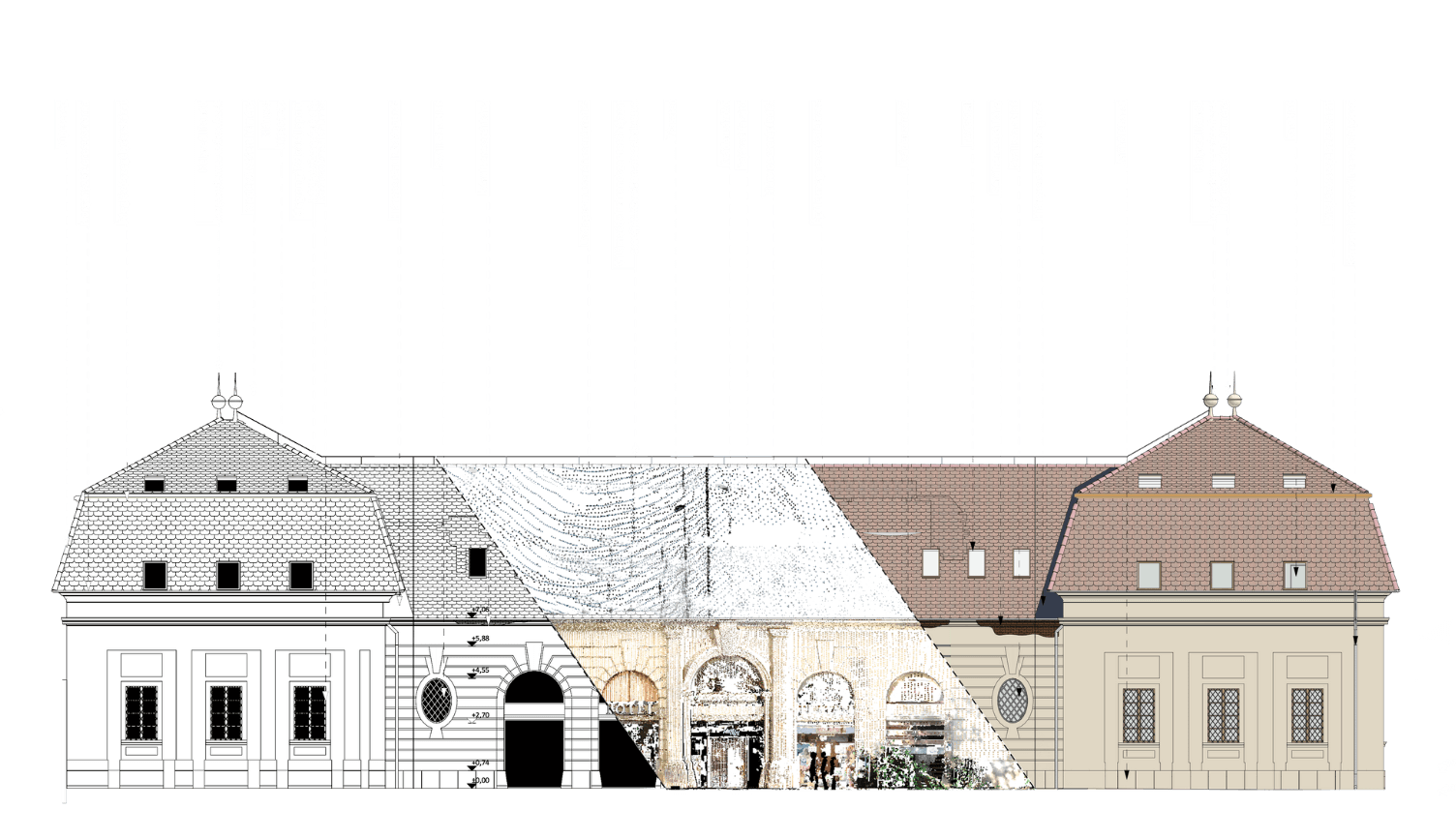

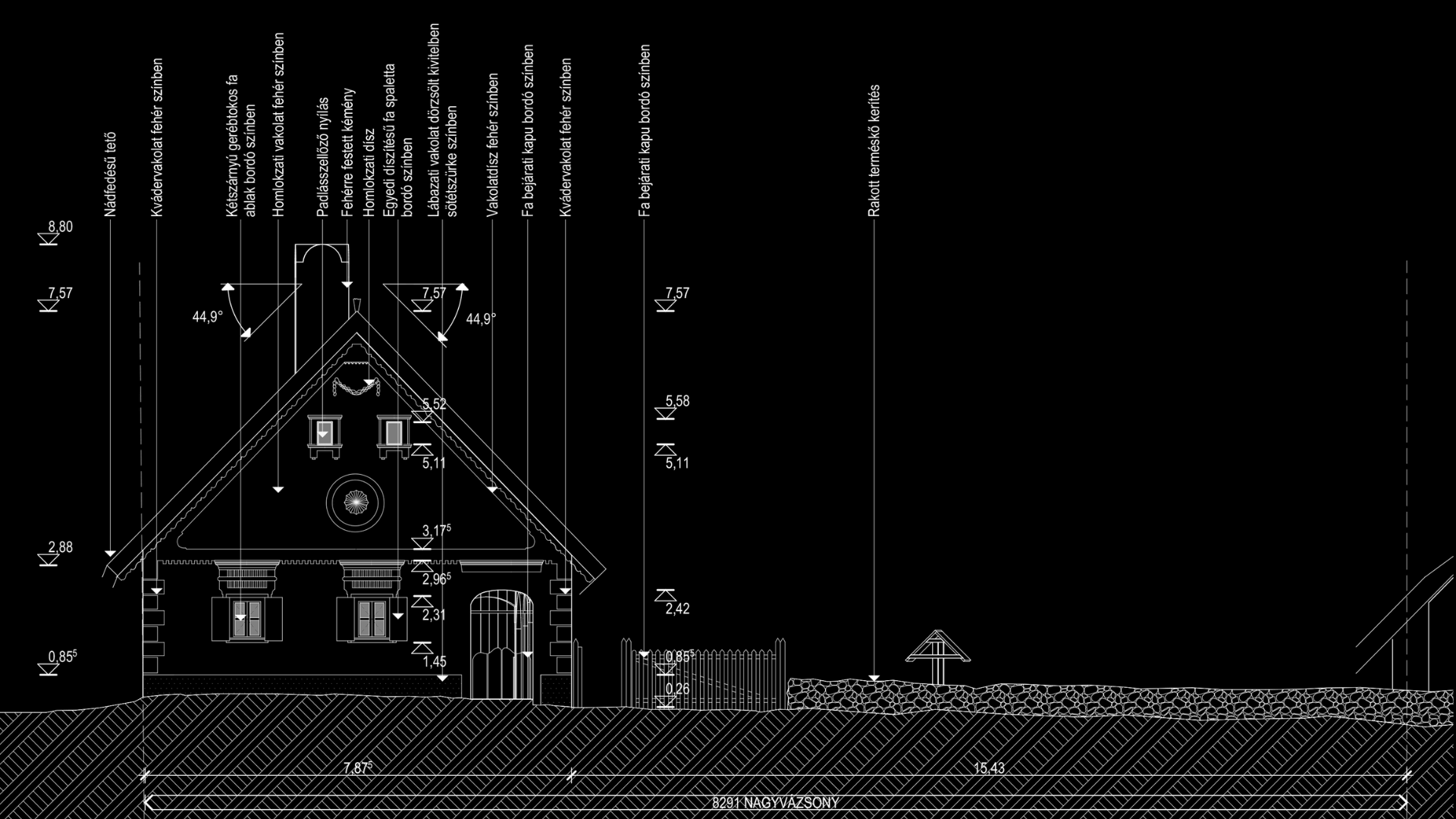

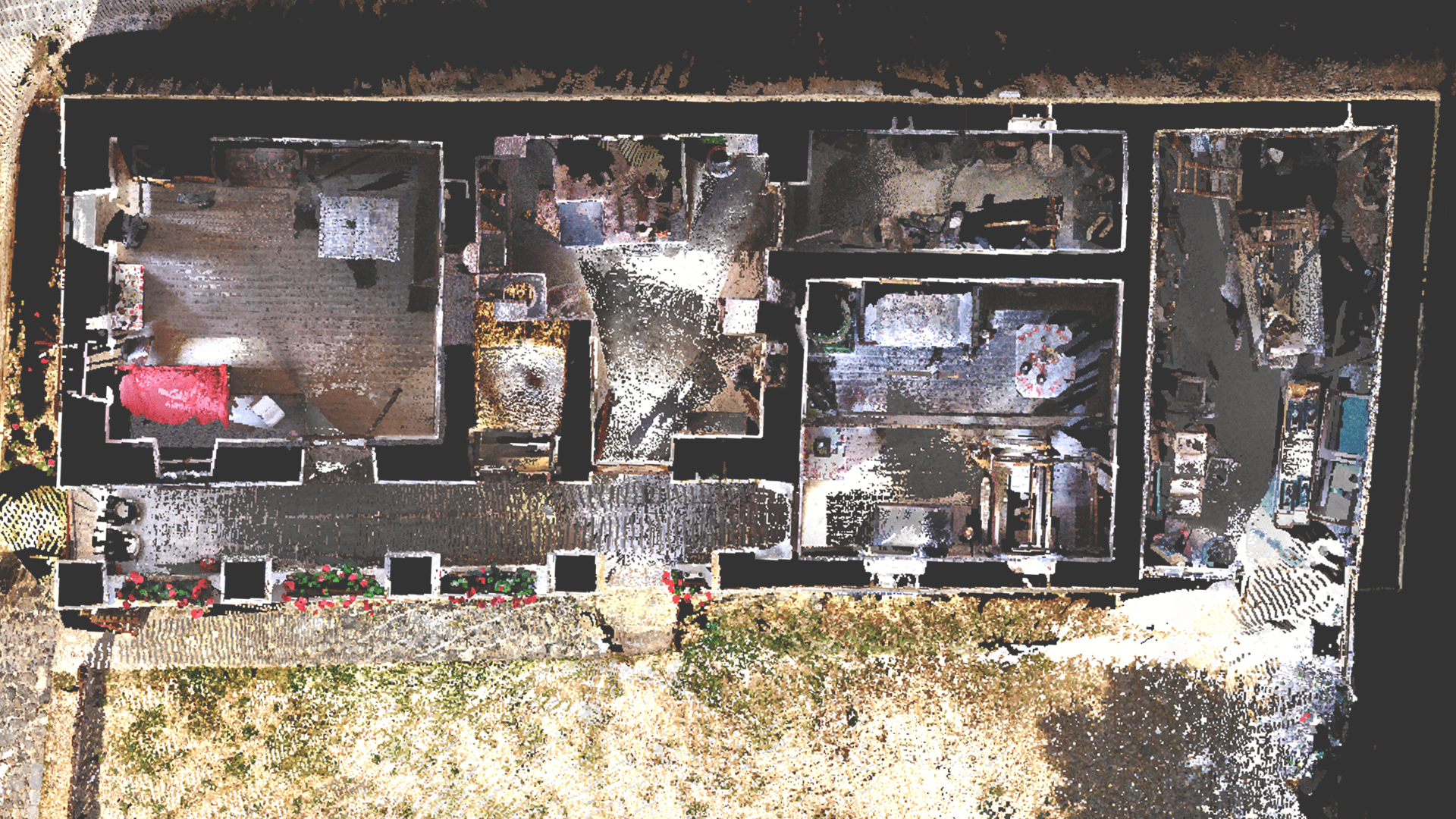

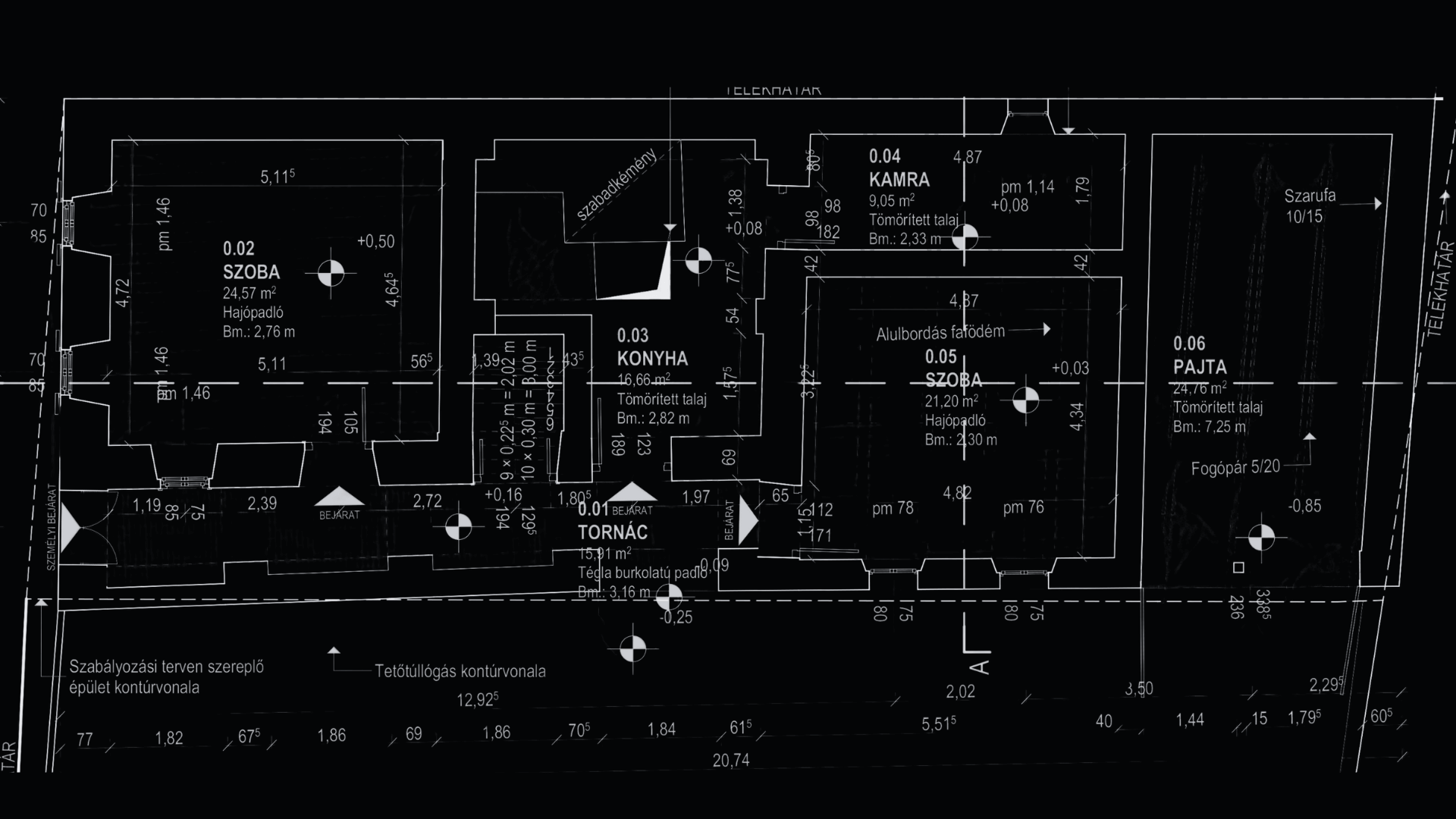

We have been commissioned to carry out a laser scanning survey of the exterior and interior of a listed building in Nagyvázsony, and to prepare the related 3D model and survey design documentation. The building had good perimeter access, so the measurements were unhindered. The large pitch of the roof provided a favourable angle of view and therefore no separate drone survey was required. After the survey, the complete point cloud was completed the next day and delivered to the client in the requested format after verification. The detailed 3D model and survey plans took a further ten working days to complete.

We were commissioned to carry out a laser scanner survey of the Central Warehouse of the University of Pécs. The 1800 m² built-up area of the building consists of three separate parts: a warehouse, a garage and an office building. The total floor area is 7500 m². The scanning and point cloud matching were carried out in parallel, so that by the fourth day we were able to complete the entire building survey and point cloud generation. The result of this work was a detailed point cloud that included the exterior and interior spaces, the elevator shaft, the mechanical level and two independent tunnels. This was handed over to the client after the checks. Scanning the entire accessible area and matching the measurements allowed us to get a thorough understanding of the building. This was a great advantage when creating the survey plan: the 3D model could be created much faster than if we had known the building solely from the point cloud. This was appreciated by the client, and we were commissioned to create the 3D model and to prepare the architectural survey documentation.